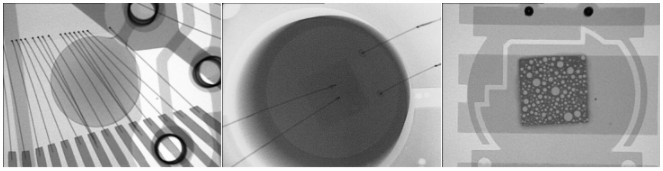

x-ray detection map

X-ray inspection equipment HT300L is a brand-new online X-Ray inspection system launched by Ailante to meet customers' needs for X-ray inspection with beautiful appearance, large detection area, strong resolution and high magnification. The system uses an enclosed ray source and a flat panel detector as the core components, and has excellent detection results. It is suitable for the inspection of LED chips, LED internal bonding wires, LED crystal wires, semiconductors, packaging components, electronic connector module inspection, photovoltaic industry and other industries.

Its main features are:

▼ Equipped with a maintenance-free sealed tube type micro-focus X-ray tube, which has a long service life and low maintenance costs

▼ High resolution, the smallest defect can be detected 2um

▼ Dimensional measurement: distance measurement can be performed at 2 points, the angle between lines and radians is automatically calculated

▼ Measurement of LED package bubble rate: After setting the limit value, it can distinguish between qualified and unqualified products based on automatic calculation.

▼ Detector rotation detection, even if the defect part is not easy to find from the vertical direction, it can be detected by oblique perspective.

National Service Hotline

ELT Technology Co., Ltd. All rights reserved

Address: 3rd Floor, Building B, Building 3, Building 2, Guangshen Road, Chaogang Town, Songgang Town, Bao'an District, Shenzhen, China.

Tel: 0755-29411968

Fax: 0755-27330185

E-mail :elt@elt-usa.com

Website: Http://www.bingjunet.cn

Wechat Public Number

Mobile website